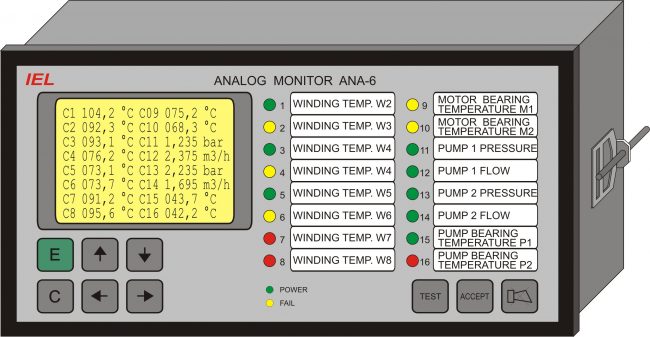

Analog Monitor is used in all the plants where continuous measurements and monitoring of the alarm states are needed. In addition to analog values, digital alarm states can also be monitored. Analog monitors accepts direct connection from measuring sensors with 0(4) -20mA current output, or 0-10V voltage output, or resistive sensors e.g. Pt-100 temperature sensors, without additional transducers, as well as moisture and temperature sensors STH-3.

Based on acqired data and defined algorithms or tables, the monitor can calculate derived quantities (e.g. flow from Q/h diagram, mean value, measured value gradient, etc.).

The application of microprocessor technology ensures fulfillment of the most demanding requirements regarding accuracy, reliability and availability of analog monitors in process or power plants.

[showhide type=”opis” more_text=”Show more” less_text=”Show less”]

- microcontroller processing up to 16 analog and 16 digital quantities

- direct resistor sensor connection without measuring transducers (Pt100)

- four alarm limits per measured channel

- high accuracy of measurement

- graphic LCD for user-process communication (display of measured values, alarm, parameterization, etc.)

- registration of the last twenty alarms with a time stamp (optional)

- tracking the mean value of multiple measuring points, deviation of the individual points from the mean value as well as the gradient of the measured value (optional)

- real time clock (optional)

- self-test function, local and remote signalling of the availability of the monitor

[/showhide]